The Industrial Internet of Things (IIoT) is transforming the way industries operate, enabling companies to optimize their processes, reduce costs, and improve efficiency. By connecting machines, sensors, and devices to the internet, IIoT allows for real-time data collection, analysis, and decision-making. In this blog post, we will explore how IIoT is revolutionizing manufacturing, supply chain management, and predictive maintenance.

Impact of IIoT on Manufacturing

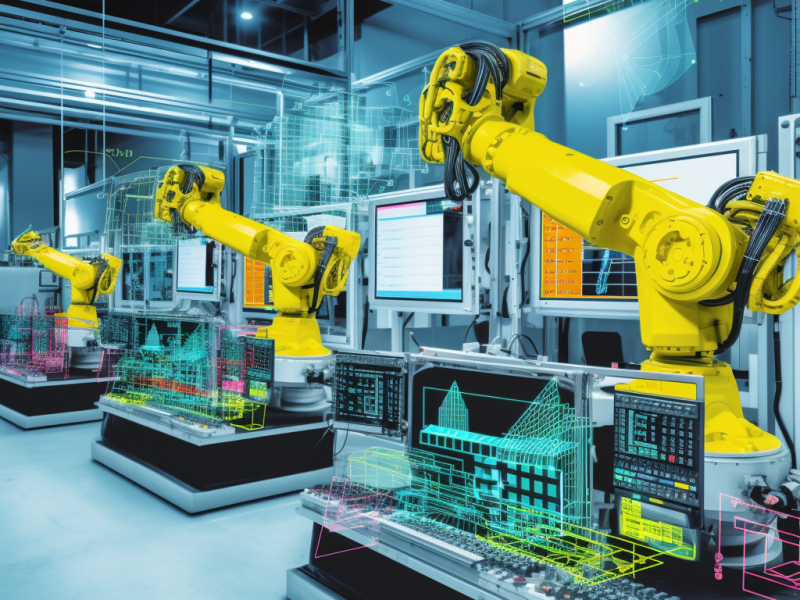

IIoT is transforming the manufacturing industry by enabling smart factories. By connecting machines and sensors, manufacturers can collect real-time data on production processes, allowing for better monitoring, control, and optimization. This data can be used to identify bottlenecks, reduce waste, and improve product quality. Additionally, IIoT enables remote monitoring and control of manufacturing processes, allowing for greater flexibility and responsiveness to changing market demands.

IIoT in Supply Chain Management

IIoT is also revolutionizing supply chain management by enabling real-time tracking and monitoring of goods throughout the supply chain. By attaching sensors to products and containers, companies can track their location, condition, and status in real-time. This data can be used to optimize logistics, reduce inventory costs, and improve customer service. Additionally, IIoT enables better collaboration between supply chain partners, allowing for more efficient and responsive supply chain operations.

Predictive Maintenance using IIoT

One of the most significant benefits of IIoT is its ability to enable predictive maintenance. By collecting data on machine performance and condition, companies can predict when maintenance is needed before failures occur. This allows for more efficient maintenance scheduling, reduced downtime, and lower maintenance costs. Additionally, predictive maintenance can improve machine reliability and extend the lifespan of equipment.

Challenges and Opportunities in Implementing IIoT

While IIoT offers significant benefits, there are also challenges in implementing it. One of the biggest challenges is ensuring the security of IIoT systems and data. With the increasing number of connected devices and sensors, there is a greater risk of cyber attacks and data breaches. Additionally, implementing IIoT requires significant investment in infrastructure, technology, and training.

Despite these challenges, the opportunities for IIoT are vast. By embracing IIoT, companies can gain a competitive advantage through improved efficiency, reduced costs, and better customer service. Additionally, IIoT enables new business models and revenue streams, such as offering predictive maintenance as a service.

In conclusion, IIoT is transforming the way industries operate, enabling companies to optimize their processes, reduce costs, and improve efficiency. By revolutionizing manufacturing, supply chain management, and predictive maintenance, IIoT is creating new opportunities for growth and innovation. While there are challenges in implementing IIoT, the benefits far outweigh the risks. As more companies embrace IIoT, we can expect to see significant improvements in industrial performance and competitiveness. Ready to harness the power of Industrial IoT for your business? Contact our experts today to learn how we can help you optimize your manufacturing processes, streamline your supply chain, and implement predictive maintenance. Don’t miss out on the opportunities IIoT can bring to your organization.