Product Lifecycle Management (PLM) is a critical approach for managing the entire lifecycle of a product from its conception to retirement. It involves a series of stages and utilizes various tools and software to streamline the process. In this blog post, we’ll explore the key stages of the product lifecycle and the tools and software commonly used in PLM.

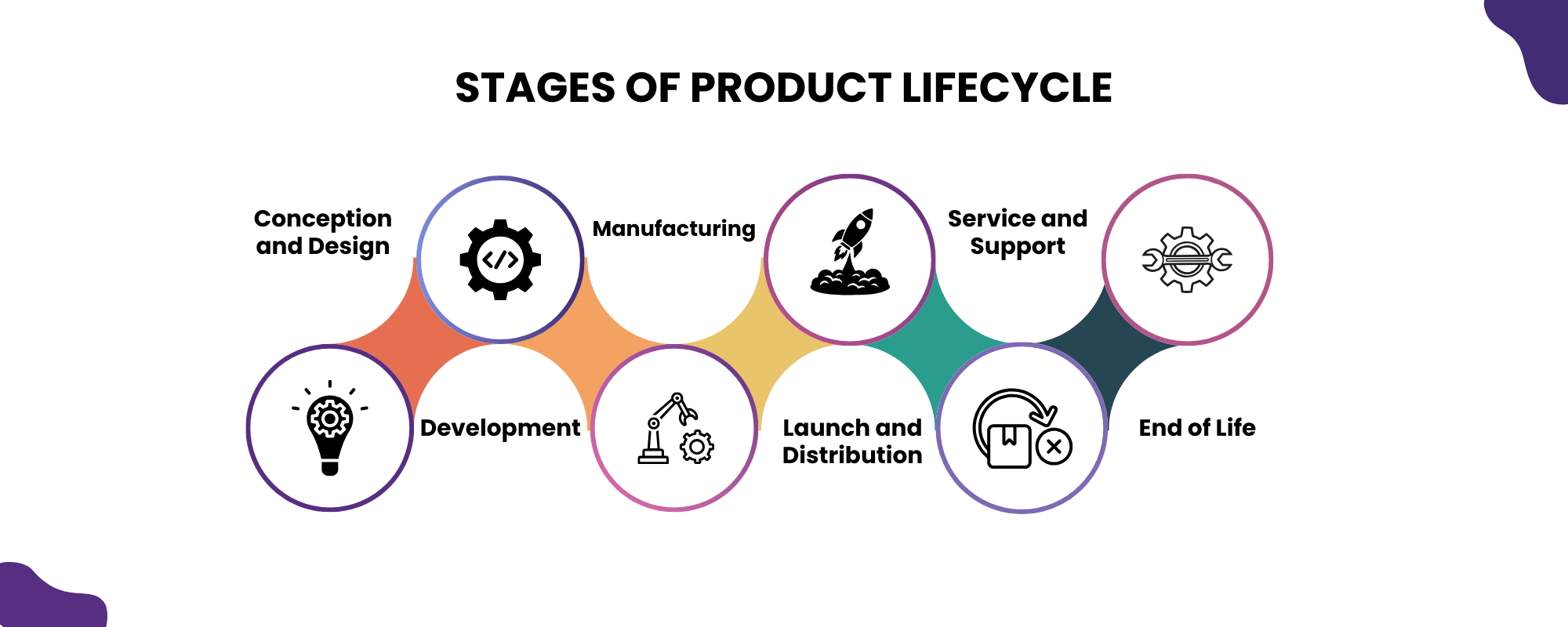

Stages of Product Lifecycle

Conception and Design

This initial stage involves generating ideas, defining product requirements, and creating conceptual designs. It includes market research, feasibility studies, and product specifications.

Development

In this stage, the product design is refined, prototypes are created, and testing is conducted. Engineering, prototyping, and validation processes take place to ensure the product meets the desired specifications.

Manufacturing

Once the product design is finalised, it enters the manufacturing stage. This involves production planning, sourcing materials, and the actual manufacturing process. Quality control and compliance with regulations are crucial during this stage.

Launch and Distribution

After the product is manufactured, it is launched into the market. This stage includes marketing campaigns, sales strategies, and distribution logistics to ensure the product reaches the target customers effectively.

Service and Support

Once the product is in the hands of customers, ongoing service and support are provided. This includes handling customer inquiries, providing technical assistance, and managing warranty and repair services.

End of Life

When a product reaches the end of its life cycle, it is typically retired or phased out. This stage involves managing inventory, discontinuing production, and handling the disposal or recycling of the product.

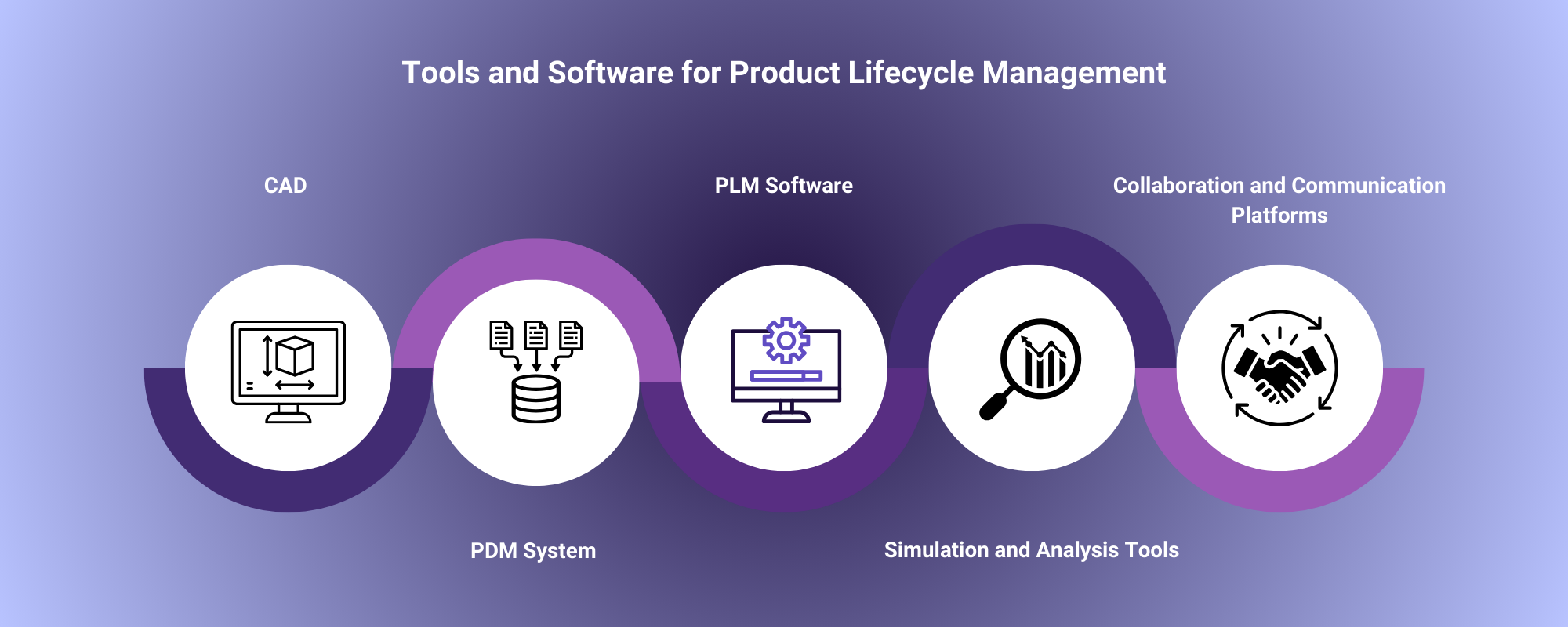

Tools and Software for Product Lifecycle Management

To effectively manage the product lifecycle, various tools and software solutions are utilized. Some common Product Lifecycle Management tools and software include:

- CAD (Computer-Aided Design) Software: CAD software is used for creating digital product designs, 3D models, and technical drawings. Examples include AutoCAD, SolidWorks, and CATIA.

- PDM (Product Data Management) Systems: PDM systems help manage and track product-related data, documents, and files throughout the lifecycle. They provide version control, access control, and collaboration features.

- PLM Software: Comprehensive PLM software solutions integrate various aspects of product development, including design, manufacturing, and supply chain management. Examples include Siemens Teamcenter, PTC Windchill, and Oracle Agile PLM (Product Lifecycle Management).

- Simulation and Analysis Tools: These tools enable virtual testing and analysis of product performance, durability, and reliability. They help identify potential issues early in the development process.

- Collaboration and Communication Platforms: PLM often involves cross-functional teams, making collaboration and communication tools essential. These platforms facilitate real-time collaboration, document sharing, and project management.

By understanding the stages of the product lifecycle and leveraging the right tools and software, companies can effectively manage their products from concept to retirement. PLM helps streamline processes, reduce time-to-market, improve product quality, and enhance overall efficiency.

Implementing a comprehensive PLM strategy offers numerous benefits. It helps reduce time-to-market by optimizing the product development process, from conception to launch. Product Lifecycle Management also enhances product quality by facilitating rigorous testing, analysis, and validation at each stage. Additionally, it improves efficiency by centralizing product data, enabling seamless collaboration among cross-functional teams, and automating workflows.

Moreover, Product Lifecycle Management plays a crucial role in ensuring regulatory compliance and meeting customer demands. By managing product data effectively, companies can track and maintain compliance with industry standards and regulations. PLM also enables better customer support by providing access to accurate product information, facilitating efficient service and support processes.

As the business landscape becomes increasingly competitive and customer expectations continue to rise, adopting a robust PLM approach becomes essential for success. Companies that invest in PLM tools and software, along with a well-defined PLM strategy, can gain a significant competitive advantage. They can respond quickly to market changes, innovate faster, and deliver high-quality products that meet customer needs.

However, implementing Product Lifecycle Management is not without challenges. It requires a significant investment in technology, processes, and people. Organizations must carefully select the right PLM tools and software that align with their specific requirements and integrate seamlessly with existing systems. They must also foster a culture of collaboration and provide adequate training to ensure successful adoption and utilization of PLM practices.

In conclusion, Product Lifecycle Management is a powerful approach that enables companies to efficiently manage their products from concept to retirement. By leveraging the right tools, software, and strategies, organisations can optimize their product development processes, improve product quality, and enhance overall business performance. Embracing PLM is no longer a choice but a necessity for companies striving to remain competitive in today’s dynamic and innovation-driven market. Ready to transform your product lifecycle management? Contact us today to learn how our PLM solutions can help you streamline processes, improve collaboration, and drive innovation. Let’s discuss your specific needs and find the right PLM strategy for your organization. Reach out now and take the first step towards optimizing your product development journey!